Description

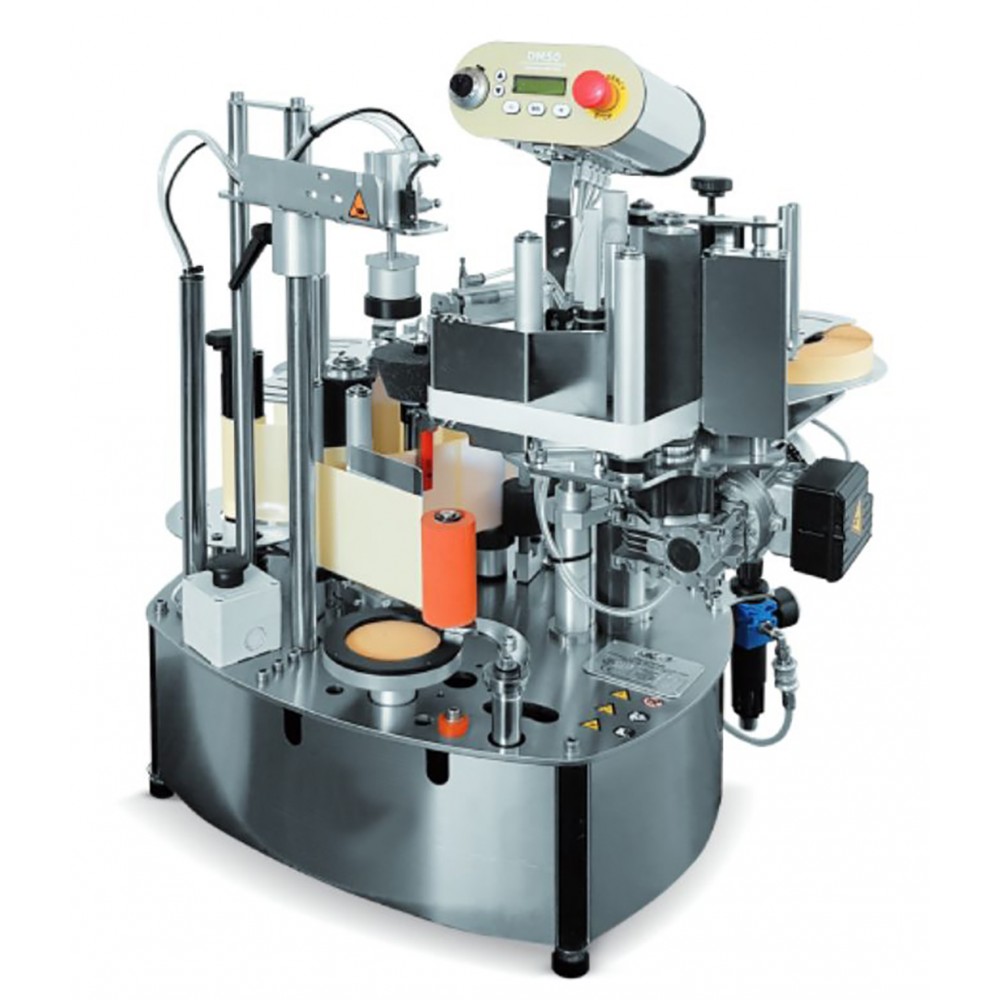

The labeling machine is equipped as standard with the following groups:

Label station

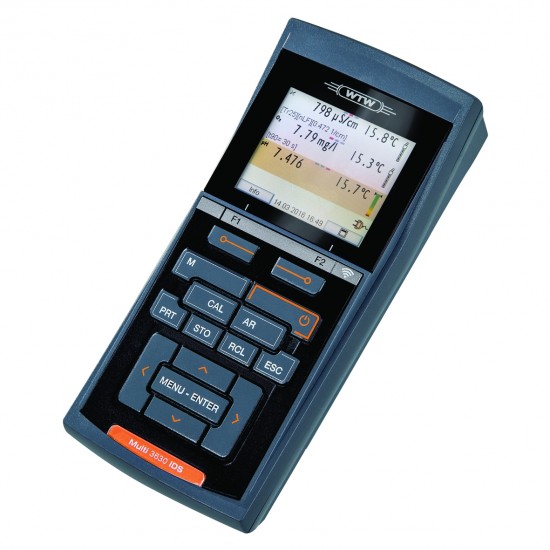

Digital control board

Rotation plate group

Upper locking pad

The labeling system takes place through a rotation plate and a pneumatic locking of the container neck, which allow to label multiple types of containers with the same equipment and at a very low cost for format changes. The machine management software is accessible via the display with the possibility of memorizing up to 19 different labeling programs.

Manual bench labeling machine with rotation plate equipped with a station for applying self-adhesive labels on cylindrical, square, conical or shaped containers, also recommended for containers with poor mechanical resistance to pressure, for example P.E.T. Bottle insertion direction: vertical. Possibility of installing a second labeling station for the application of either the back label or the crewneck collar.

Customizable machine: thanks to the modular design, each piece of equipment can be modified ad hoc to meet the specific needs of the customer, through the creation of special groups tailored to the individual order.

On request, it is possible to carry out a packaging test using the samples of bottles and labels provided by the customer, who can view the labeling results on their products via video or directly in person.

Our After-Sales and Technical Assistance department is able to assist the customer even remotely using the current video conferencing and remote desktop tools.

Our technical-commercial department is at the customer's disposal to support him also in the choice of materials (container and labels) and of the complementary equipment to the packaging process, thanks also to the experience acquired in over 40 years of activity in the packaging sector by of the owner and TDO manager.