Air cooled liquid chiller - Super low noise acoustic configuration 232 - 1334 kW

Air cooled liquid chiller - Super low noise acoustic configuration 232 - 1334 kW

NITROGEN GENERATOR CHALLENGER SERIES 126 m³ / hour

Ozone generator for small/medium enclosed spaces - 80 mc max

Air cooled liquid chiller - Low noise acoustic configuration 228 - 867 kW

Housing 1 filter system with 12 cartridges

Ozone water and air generator with lance and pressure gun

FILLING MACHINE with DEPRESSION 230V side discharge at constant preset level 2-3-4-6-8 Nozzles

NITROGEN GENERATOR CHALLENGER SERIES 140 m³ / hour

NITROGEN GENERATOR CHALLENGER SERIES 70 m³ / hour

Air cooled liquid chiller - Basic acoustic configuration 375 - 1908 kW

Laboratory mixer max capacity ml 1000

MANUAL LABELLER round and square bottles 150-200 bottles/hour

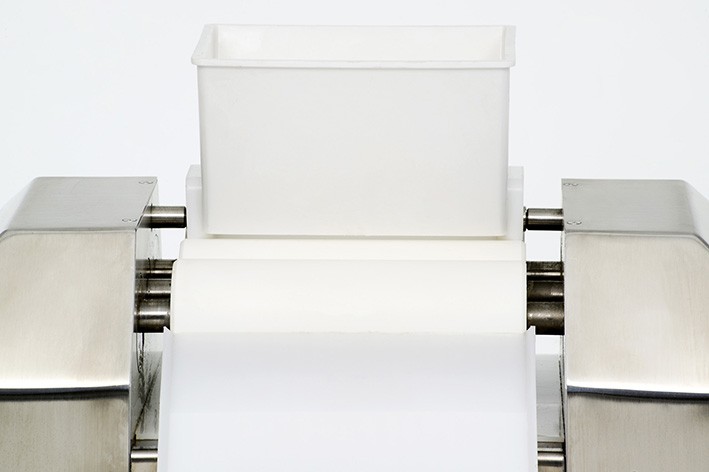

DOSING MACHINE for liquid or semi-solid - 380 1 litre containers per hour