NITROGEN GENERATOR "AP" 3 Nmc/h

NITROGEN GENERATOR "AP" 3 Nmc/h

NITROGEN GENERATOR "Mini Gaz" 0.25 Nmc/h

Floating stator progressive cavity pump - 8.5 hectolitres/hour - WITH THREE-PHASE INVERTER AND...

PISTON FILLER with preset constant volume - 1 or 2 dispensers

NITROGEN GENERATOR "Mini Gaz" 0,5 Nmc/h

Semi-automatic rinsing machine 2 and 4 injectors

Single-screw floating stator pump 900 rpm - 18 quintals/hour - THREE-PHASE

SEMIAUTOMATIC LABELLER FOR BENCH (cylindrical and conical formats - 700 bottles/hour)

Aphrometer for bottles with Stelvin aluminium cap diameter 87 - height 307 mm

Floating stator progressive cavity pump 10-2000 rpm - 2-53 hectolitres / hour - THREE-PHASE...

NITROGEN GENERATOR CHALLENGER SERIES 126 m³ / hour

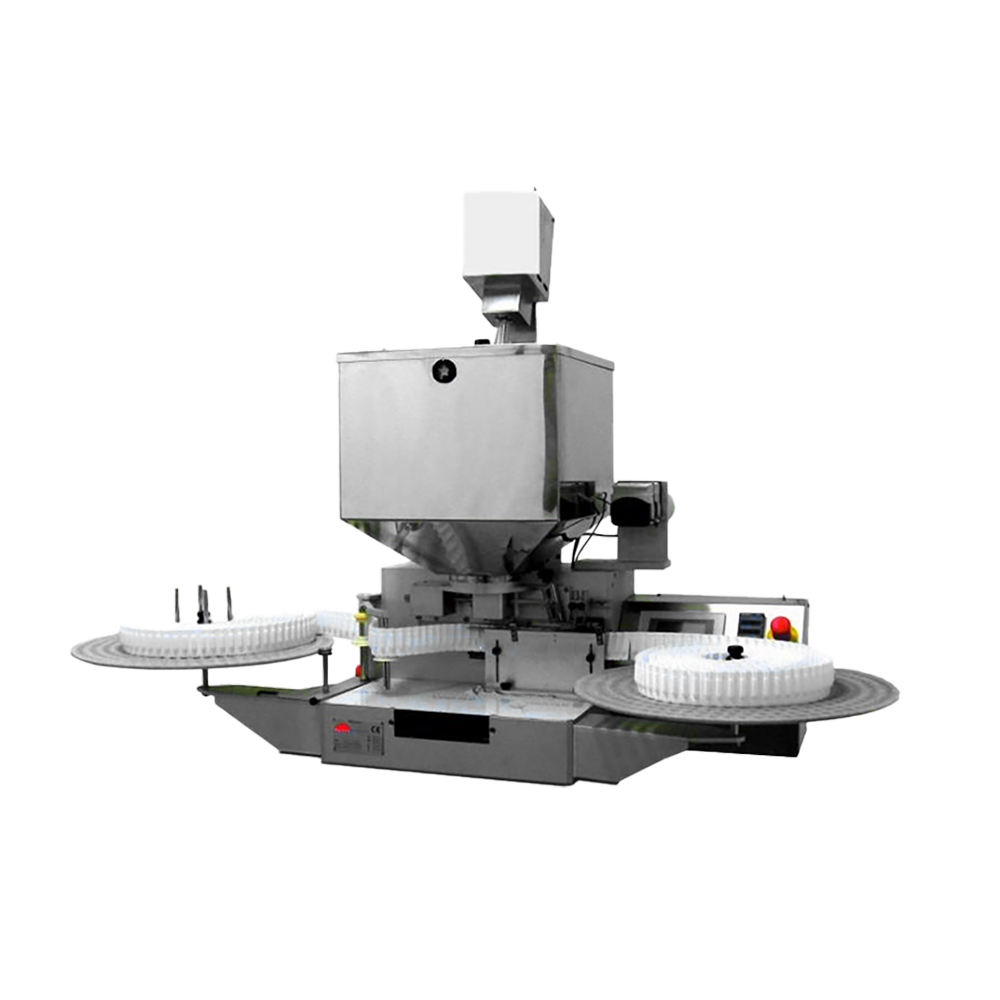

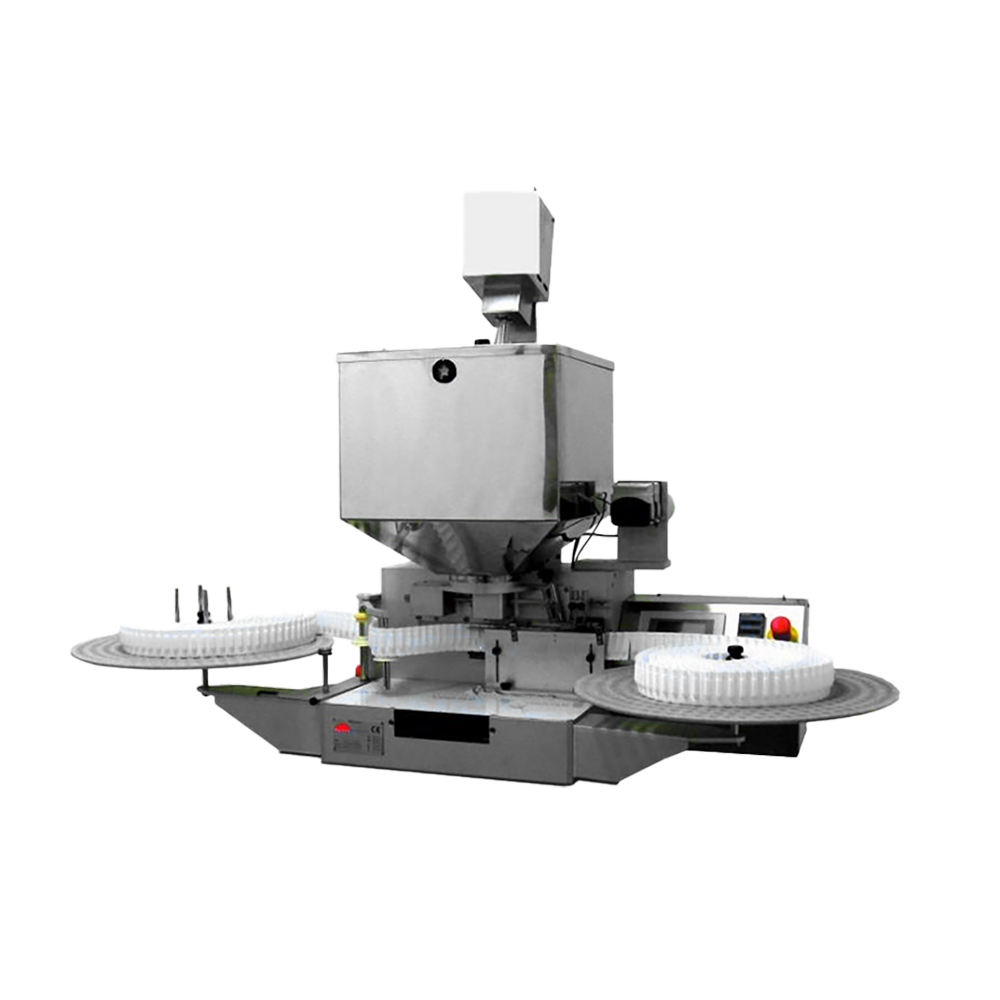

DOSING MACHINE for liquid or semi-solid - 380 1 litre containers per hour

SEMIAUTOMATIC LABELLER FOR BENCH (cylindrical, conical, shaped formats - 700 bottles/hour)